There are several automation systems utilized onboard ship to ensure efficient and smooth running of the Machinery. However, machines still fail, mainly because of the lack of knowledge of the crew on that particular system. For this reason it is is very important to install and maintain the system in correct order to avoid any damage to the machinery.

What is Spark Erosion?

Technically, when two current carrying dissimilar metals are in contact, a sparks travels at the point of contact which erodes the small metal by making a cavity.

In a Vessel, different metals are used to building propeller, hull, bedplate, crankshaft, bearing etc. The current from the cathodic protection system is generally present in these parts, which eventually creates the perfect situation for spark erosion.

Even a ship’s hull made up of steel which is immersed in sea water, small galvanic current flows through anodic area leading to corrosion and erosion.

Effects of spark erosion

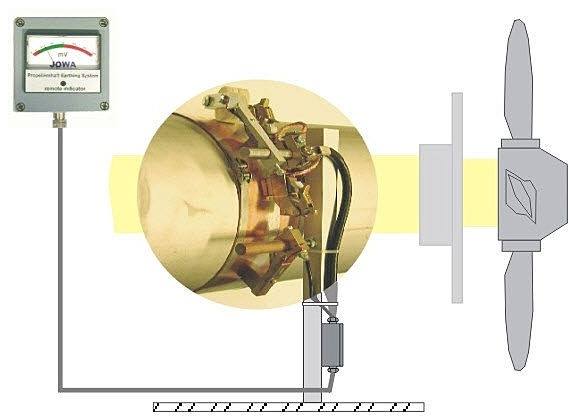

To suppress the effect of galvanic corrosion, especially at the stern part of the ship where the propeller is present, an Impressed Current Cathodic Protection system is used. The propeller shafting is earthed to achieve continuous circuit and to avoid malfunction of the same.

When the propeller is at rest, the stern tube, propeller shaft and bearings are in contact with each other. Similarly main engine bearing and journal are in contact with each other, maintaining continuity of the circuit. When the ship is running, due to the rotation of the propeller and lubricating oil film the shaft becomes partially electrical insulated. It may also happen on the tail shaft using non metallic bearing which acts as an insulation.

The propeller at the aft is a large area of exposed metal which attracts protective cathodic current which produces an arc while discharging from the lubricating film. This results in spark erosion of bearings, which can lead to worse situation if lube oil is contaminated with sea water.

If this effects continue for a considerable amount of time, it may lead to overheating of Main engine bearings caused by improper lubrication resulted by cavities from spark erosion. It may also lead to formation of oil mist, emergency shutdown of the engine or in extreme cases crank case explosion.

Reasons for Spark Erosion

Some of the main reasons which results in Spark erosion related problems on ship are

- The shaft earthing arrangement is not working or improperly fitted

- The Cathodic protection current system setting is wrong

- The hull coating is excessive than required which will increase the galvanic corrosion of the shaft

- Slip rings and brushes in the earthing device are worn out

- The contact between shaft and earth device is not clean

It is advisable to use two earthing devices for the shaft of the main engine. One for earthing purpose and the other to connect with the voltmeter for measuring the potential difference between the shaft and the hull of the ship.

The effect of spark erosion will be minimum if the potential difference is below 50 mv.

Source: www.marineinsight.com

Comments

Post a Comment